energy drink manufacturing process Process drink production energy line manufacturing soft automatic sgs details

In today’s fast-paced world, the demand for energy drinks is skyrocketing. People are constantly looking for that extra boost of energy to power through their busy lives. Have you ever wondered how these popular drinks are manufactured? Let me take you on a virtual tour of a full automatic soft drink production line for energy drink manufacturing process.

Full Automatic Soft Drink Production Line For Energy Drink

The image above showcases a state-of-the-art production line designed specifically for energy drink manufacturing. This fully automated system is capable of producing anywhere between 3000 to 20000 bottles per hour, ensuring a continuous supply of your favorite energy drinks.

The image above showcases a state-of-the-art production line designed specifically for energy drink manufacturing. This fully automated system is capable of producing anywhere between 3000 to 20000 bottles per hour, ensuring a continuous supply of your favorite energy drinks.

The process begins with the careful selection of high-quality ingredients. These include water, flavorings, sweeteners, and caffeine. Each ingredient is meticulously measured and blended to create the perfect energy drink formula.

Once the ingredients are mixed, they are sterilized to ensure product safety and longevity. The sterilization process involves subjecting the mixture to high temperatures, killing any bacteria or pathogens that may be present.

The next step in the production line is the carbonation process. Carbon dioxide gas is injected into the mixture, creating that signature fizz and refreshing taste that energy drinks are known for. This step requires precision and careful monitoring to achieve the desired level of carbonation.

After carbonation, the energy drink is ready to be filled into bottles. The production line is equipped with advanced bottle filling technology that ensures accurate and efficient filling. Each bottle is precisely filled to the desired level, preventing any spillage or wastage.

Once the bottles are filled, they are capped and sealed to maintain freshness and prevent any leakage. The production line incorporates a highly efficient sealing mechanism that ensures each bottle is properly sealed, extending the shelf life of the energy drink.

The final step in the production line is packaging. The bottles are carefully transported to the packaging area, where they are grouped and labeled. This automated process ensures that the energy drinks are neatly packaged and ready for distribution to stores and consumers.

Throughout the entire production line, strict quality control measures are in place to ensure that each bottle of energy drink meets the highest standards. Regular quality checks and inspections are performed to detect any deviations from the desired specifications.

CANNING SOFT DRINKS AUTOMATED FACTORY PROCESS

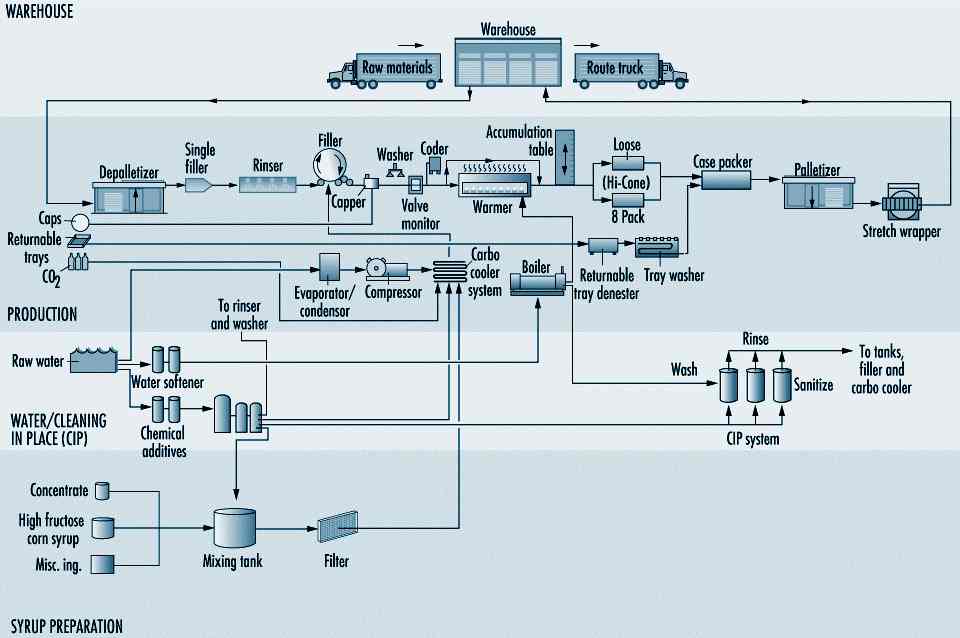

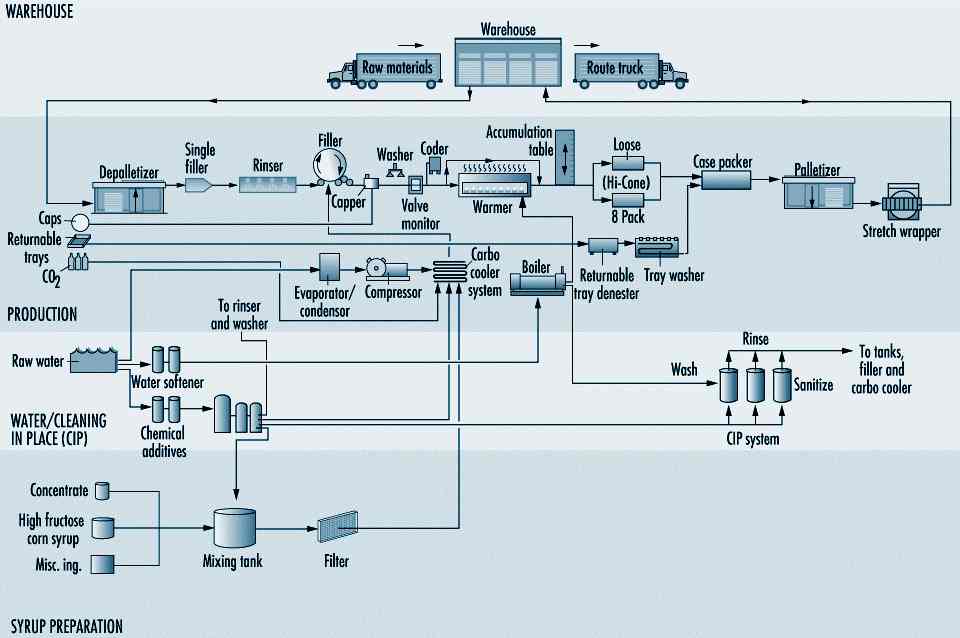

Another essential component of the soft drink manufacturing industry is the canning process. The image above illustrates an automated factory process specifically designed for canning soft drinks.

Another essential component of the soft drink manufacturing industry is the canning process. The image above illustrates an automated factory process specifically designed for canning soft drinks.

The canning process starts with the careful selection of aluminum cans that are perfect for storing and preserving soft drinks. These cans are meticulously cleaned and sanitized before moving on to the filling stage.

The automated filling machines in this factory process accurately fill each can with the desired soft drink. A precise amount of the energy drink formula is measured and filled into each can, ensuring consistent quality and taste.

Once the cans are filled, they move on to the sealing stage. A high-speed sealing machine quickly and efficiently seals each can to prevent any leakage or contamination. The sealed cans are then labeled and packaged for distribution.

Both the soft drink production line and the canning process offer a glimpse into the fascinating world of energy drink manufacturing. These fully automated systems not only ensure efficiency and accuracy but also play a crucial role in meeting the ever-growing demand for energy drinks.

So, the next time you crack open a can or pop the cap on an energy drink, take a moment to appreciate the intricate processes involved in its production. From the selection of ingredients to the final packaging, the entire energy drink manufacturing process is a testament to the dedication and innovation of the industry.

If you are searching about Universal Beverages Factory: Dubai you’ve came to the right place. We have 5 Images about Universal Beverages Factory: Dubai like Universal Beverages Factory: Dubai, Full Automatic Soft Drink Production Line For Energy Drink and also AODD Pumps can put the “Pop” in Soda Production - Empowering Pumps and. Here you go:

Universal Beverages Factory: Dubai

universalbeveragesfactory.comproviding contract

universalbeveragesfactory.comproviding contract

Full Automatic Soft Drink Production Line For Energy Drink

www.drinkprocessing.comprocess drink production energy line manufacturing soft automatic sgs details

www.drinkprocessing.comprocess drink production energy line manufacturing soft automatic sgs details

Full Automatic Soft Drink Production Line For Energy Drink

www.drinkprocessing.comtunnel juice process sterilizing beverage automatic produksi drinkprocessing energi minuman proses penuh lini

www.drinkprocessing.comtunnel juice process sterilizing beverage automatic produksi drinkprocessing energi minuman proses penuh lini

CANNING SOFT DRINKS AUTOMATED FACTORY PROCESS

www.solarnavigator.netsoft canning process drink flow chart factory drinks solar figure operations bottling basic automated

www.solarnavigator.netsoft canning process drink flow chart factory drinks solar figure operations bottling basic automated

AODD Pumps Can Put The “Pop” In Soda Production - Empowering Pumps And

empoweringpumps.commanufacturing wilden energy aodd

empoweringpumps.commanufacturing wilden energy aodd

Full automatic soft drink production line for energy drink. Universal beverages factory: dubai. Process drink production energy line manufacturing soft automatic sgs details